Pipeline thermal Extension: Small Movement, Serious Consequences

Thermal expansion in industrial pipelines is predictable, yet its consequences are often underestimated. Even modest temperature shifts can cause measurable elongation, leading to misalignment, bracket deformation, and stress accumulation at welds or flanges. Effective pipeline design must anticipate this movement through deliberate support strategies, anchoring logic, and expansion accommodation.

Thermal Design Fundamentals

Every new pipeline design should begin with four key thermal conditions: the

fully empty condition (no fluid, no pressure), maximum operating temperature

(process or steam), minimum ambient or shutdown temperature, and frequency of

thermal cycling. These aren’t just numbers. They shape how the system breathes.

If ignored, they become the root of costly rework and long-term maintenance

headaches.

Pipe Support Types and Their Roles

Pipe support actively shape how a pipeline responds to thermal and mechanical

forces. Their selection must align with movement expectations, load conditions,

and environmental factors. Fixed supports prevent movement in all directions

and are used near anchors or control points. Sliding supports allow axial

movement while restricting vertical or lateral displacement. Guided supports

steer the pipe along a defined path, useful in systems with predictable

expansion. Spring supports vertical movement due to thermal expansion or load

variation. Hangers and rod support suspend piping from above, allowing limited

movement. Snubbers and shock absorbers resist dynamic loads while allowing slow

thermal movement. Misapplication of these supports can lead to stress

concentration, fatigue, and premature failure.

Case Example: DN200 Carbon Steel Pipe

Under Steam-Out

Consider a DN200 (8") carbon steel pipe undergoing steam-out,

transitioning from ambient temperature (20 °C) to 200 °C. With a coefficient of thermal expansion of

12 × 10⁻⁶ /°C and a pipe length of 50

meters (≈ 164’), the

temperature change of 180 °C results in an elongation

of approximately 110 mm (≈ 4.25” ).

Case Example: DN200 (8") Stainless Steel Pipe (316L) Cooling Down

Scenario: A 8" stainless steel pipe

made of 316L cools from +20 °C to −60 °C.

Material: Stainless Steel 316L Coefficient

of Thermal Expansion: ≈ 16 × 10⁻⁶ /°C

Pipe Length: 400 meters (≈ 1312 feet)

Temperature Change: ΔT = −60 °C − (+20 °C) = −80 °C

Thermal Contraction Calculation: = -512 mm or 20”

Support Implication: Pipe supports are typically 30 cm long

(≈ 12"). With a contraction of 512 mm (≈ 20.16"), the pipe will shrink

away from its supports, leaving gaps far larger than the support spacing.

This

means the pipe will lift off or slide off its supports and will not naturally

return to position. This will lead to misalignment, stress on joints, and

potential mechanical failure, a problem in the making if not properly accounted

for in the design.

Be aware a ‘plastic‘

pipe extends significantly more as this example.

This movement must be absorbed safely. If

constrained improperly, it can lead to flange misalignment, weld fatigue,

bracket deformation, and stress accumulation. If steam-out occurs daily,

fatigue and wear become critical factors. Support systems must be selected and

placed to accommodate this movement without transferring stress into vulnerable

components.

Pipe(line) Design is where it starts

This piping list provides a structured

overview of process lines used in chemical plant design, construction, and

asset management. It consolidates key technical, mechanical, and regulatory

data to support safe operation, efficient procurement, and lifecycle integrity.

Each entry reflects the specific requirements of chemical media, thermal

cycles, and compliance standards such as ASME B31.3, EN 13480, and PED. The

table is designed for cross-functional use by engineering teams, inspectors,

and project stakeholders, ensuring clarity, traceability, and alignment with

best practices in the process industry.

Piping List

|

Category |

Typical Fields |

|

Line Identification |

Line number, service description, P&ID reference, unit/area,

revision status |

|

Process Details |

Fluid name, phase (gas/liquid/solid), hazardous classification,

flash point, viscosity, density, toxicity level |

|

Pipe Spec. |

CS, SS, or others, |

|

Design Parameters |

Design pressure & temperature, Operating pressure &

temperature, Steam Out conditions, Cycle rate, Corrosion allowance,

insulation/refractory details |

|

Mechanical Info |

Nominal pipe size (NPS/DN), schedule/thickness, pipe material spec

(ASTM/EN), rating class (ANSI/PN), flange type, gasket and bolting material |

|

Routing & Layout |

Start/end equipment tags, elevation changes, slope requirements,

underground/aboveground, expansion loops, supports/hangers |

|

Code & Standards |

Design code (e.g. ASME B31.3, EN 13480), PED/ATEX applicability,

welding standards (ISO 9606, EN 287), inspection class |

|

Special Requirements |

Heat tracing (electrical/steam), painting/coating system,

flushing/cleaning method, PWHT, NDT type (RT, UT, PT, MT), hydrotest pressure |

|

Valve & Fitting Info |

Valve types (gate, globe, ball, check), actuation method (manual,

pneumatic, electric), fitting specs, reducer type, tee configuration |

|

Instrumentation |

Inline instruments (flowmeter, pressure transmitter), tapping

points, thermowells, sample connections, instrument isolation valves |

|

Environmental & Safety |

Leak detection method, containment strategy, emergency isolation,

fireproofing, noise attenuation, vibration control |

|

Revision Tracking |

Revision number, date, change description, approved by, document

status |

It is not just a pipe from A to B, it is carefully

engineered!

Solving the Problem

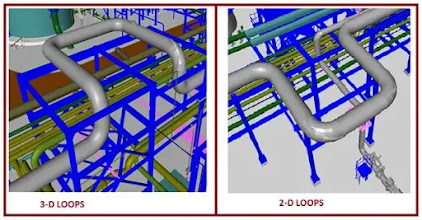

Expansion Loops: Function Over Form

Expansion loops and U-shapes are not decorative sketches. They are real-world

solutions that absorb movement and protect assets. But they only work when

sized and placed with intent. Too tight, and they don’t flex. Too loose, and

they invite instability. Designing an effective loop requires calculating

expected movement, pipe stiffness, and available space. Assumptions must be

tested. Adjustments post-installation are rarely simple.

A Pipe extending due to heating up or shortening due to cooling down

is

the same issue!

Anchoring Strategy: Control the Movement

Where the pipe is fixed—and how—dictates where it will move. Anchoring too

close to a heat source concentrates stress. Anchoring too far loses control.

Anchors placed “where convenient” are not engineering decisions. They are risks

waiting to surface.

Support Behavior Under Thermal Stress

Supports themselves expand, contract, and shift with temperature. Concrete

pedestals can crack under repeated thermal cycling. Steel brackets can warp.

Sliding plates can seize without maintenance. If the support system isn’t

designed to move with the pipe, it will eventually resist it. Resistance leads

to failure.

Designing for Inspection and Maintenance

Thermal expansion isn’t a one-time event. It happens every cycle, every season,

every shutdown. Can supports be inspected without scaffolding? Can expansion

loops be monitored for fatigue? Can anchors be adjusted if movement exceeds

expectations? Designing for inspection and maintenance separates short-term

success from long-term reliability.

Material Behavior and Weld Integrity

Different materials expand at different rates. Stainless steel, carbon steel,

HDPE—they all behave differently under heat. Welds are often the weakest link.

If expansion stresses concentrate near a weld, fatigue is inevitable,

especially in high-cycle systems. Golden joints, torquing protocols, and NDT

aren’t just quality checks. They are expansion safeguards.

Mitigation Strategies That Work

Thermal expansion can’t be eliminated, but it can be managed. Effective

mitigation starts with understanding the movement profile and designing the

system to absorb, redirect, or accommodate that movement without transferring

stress into vulnerable components. Common strategies include expansion loops:

U-shaped bends in the pipeline absorb axial movement. For example, a 50-meter

DN200 carbon steel steam line expanding by ~108 mm can be stabilized using two

properly sized loops placed at calculated intervals. These loops must be

supported by guided clamps and anchored to control the direction of movement.

Expansion joints, metallic bellows or rubber joints, allow movement while

maintaining pressure integrity. These are especially useful in retrofit

scenarios or confined spaces where loops aren’t feasible. However, they require

careful placement and regular inspection to avoid fatigue or seal failure.

Changes in direction, such as elbows and

offsets, naturally absorb some expansion. A long run with two 90° elbows can

tolerate moderate movement if the supports allow flexing. This method is often

used in building risers or utility corridors. Sliding and guided supports allow

the pipe to move along its axis while preventing lateral drift. For instance,

steam lines in industrial plants often use PTFE-lined sliding shoes to reduce

friction and wear. Anchoring logic is also critical. Strategic placement of fixed

points ensures that expansion is directed toward safe zones. Anchors should be

located away from heat sources and paired with expansion accommodation

downstream.

Each mitigation method must be tailored to

the pipe material, operating temperature, cycling frequency, and spatial

constraints. Overdesign leads to cost and complexity. Under design leads to

failure.

For some more detailed guidance, Walraven

offers a practical overview of thermal

pipe expansion strategies.

Design Decisions Are Legacy Decisions

Every pipeline design will outlive its drawings. It will be operated,

maintained, and modified by people who weren’t in the room when decisions were

made. So those decisions must be clear, deliberate, and documented. Thermal

movement is not a nuisance. It’s a natural behavior. And like all natural

behaviors, it demands respect.

Let’s benchmark. What’s your go-to strategy

for managing thermal expansion in long runs or complex layouts? Any lessons

learned you’d share with younger engineers?

For more help please go to

https://triplepoint.engineering

#triplepointengineering #dickverhoeven

#pipedesign #thermalexpansion #assetintegrity #engineeringwisdom

#pressureequipmentdirective #projectclosure #mechanicalintegrity #ndtprotocols

Comments

Post a Comment